Various procedures apply to occupational health and safety dangerous or non-dangerous for the use and operation of tools and technology. In order for the employer to know what obligations he must fulfill, it is necessary to determine to which category the given work tool belongs.

What is considered a working tool?

Any machine, device, tool or equipment used in or in connection with the work, excluding personal protective equipment.

XCIII of 1993 on labor protection. The law defines the concept of dangerous as follows. A facility, work tool, material/preparation, work process, technology (including activities involving exposure to physical, biological, chemical pathogenic factors) is dangerous if the health, physical integrity, and safety of employees may be exposed to harmful effects in the absence of adequate protection.

Dangerous work tools

Dangerous work tools, dated 5/1993. (XII. 26.) MüM decree 1/a. and 1/b. Annex No. 87 and Section 11 of Act XCIII of 1993.

Work tools subject to official supervision are also classified as dangerous work tools.

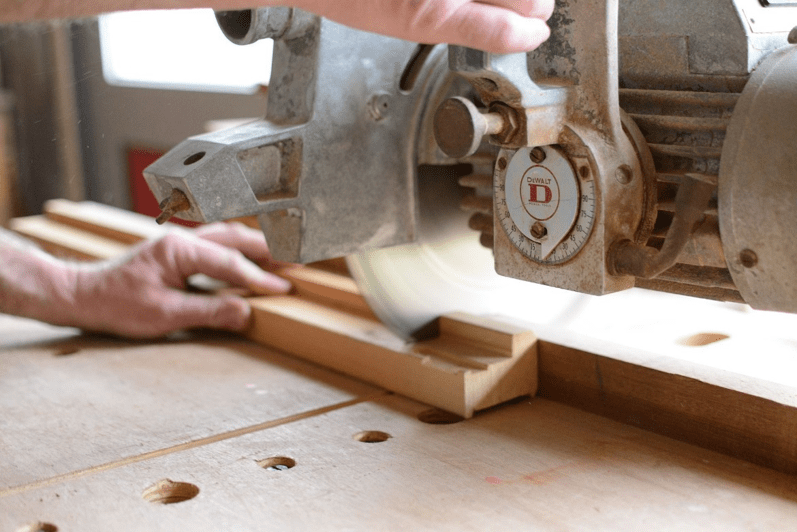

- For woodworking, meat processing or processing materials with similar physical properties to meat circular saws;

- Woodworking planer with manual feed;

- Wood industry thickness planer for one-sided processing;

- Band saws by manual insertion and/or removal, for woodworking and processing materials with physical properties similar to wood, or for meat processing and processing materials with physical properties similar to meat;

- Combined machines for working wood and materials with physical properties similar to wood;

- Wood industry tap milling machine with several tool holders, manual feed;

- Vertical milling machine manual feed for woodworking and materials with physical properties similar to wood.

- Wood industry manual chainsaw.

- For cold transformation of metals press, including that is edge bending machine also;

- Plastic processing injection molding machine obsession forming press;

- Rubber industry injection molding machine or forming press;

- Underground for work machines;

- Household with manual dosing waste collection truck, which is equipped with a press mechanism;

- Vehicle liftk;

- For lifting persons or persons and loadse serving structures;

- Portable cartridge fastening and other joining machine;

- Cranes and trolleys with mechanical drive;

- Machine driven lift trucks;

- Electric lifting drums;

- loaders, skid steer loaders;

- Agricultural and forestry tractors;

- Vehicle unloading and moving special equipment;

- Used for passenger transport continuous conveying equipment;

- Machine-driven with on-site assembly cranes;

- Vehicle unloading and moving special equipment assembled on site;

- For personal lifting can be used temporarily lifting equipment.

Dangerous work equipmentplacing it in my eye

Occupational safety commissioning the occupational safety procedure during which the operator is convinced that the given facility, workplace, technology, work equipment meets the occupational safety requirements and orders its operation. The operating employer orders the operation of the hazardous facility, workplace, work equipment, and technology in writing.

It is important that even during the test, experimental mode, the machine must have the appropriate measurement protocols and documentation. This kind of operation cannot exceed 180 days.

The condition for occupational safety commissioning is a preliminary inspection from an occupational safety point of view. The purpose of the inspection is to establish that the facility, the workplace, the work equipment, and the technology meet the physical, personal, organizational, and working environment conditions necessary for safe and health-free work, as well as fulfill the general requirements of the law. Carrying out the examination is considered an occupational safety and occupational health professional activity.

During the preliminary examination, it must be examined in particular, whether the declarations of those performing the installation (designer, contractor), measurement results proving the satisfaction of occupational safety requirements, declarations of conformity for the work equipment, certificates, the necessary official permits, the instructions for operation are available.

In addition, the condition for putting some dangerous work equipment into operation is the existence of an inspection report issued by an accredited organization based on the conformity assessment of the given work equipment and containing the results of the inspection.

Periodic safety review of hazardous work equipment

Hazardous technology and hazardous work equipment, as well as work equipment whose periodic safety review is required by legislation, standards, or documentation for proper and safe operation and use, subject to periodic safety review.

The periodic safety review must be performed by the operator every five years, if legislation, standards or the operating documentation do not require a more frequent review period.

The result of the review must be recorded in an inspection report, a copy of which must be provided to the operator. The operator is obliged to keep the inspection report until the inspection following the review.

Examination of dangerous technology it can be performed by a person with a specialized work safety expert license.

Out-of-order checks

The workplace, personal protective equipment, the work tool, the employer must check the technology out of sequence if it directly endangered the health and safety of the employee during its intended use, or in connection with this, an occupational accident occurred, or extraordinary circumstances (transformation, accident, natural phenomena or a period of non-use exceeding 30 days for technical reasons) in case of occurrence. Carrying out the inspection is considered an occupational safety and health professional activity.

Pre-restart test

If, for any reason, the dangerous machine, technology, or equipment has been stopped and a change or repair or relocation involving complete disassembly has been carried out, a new commissioning test must be performed.